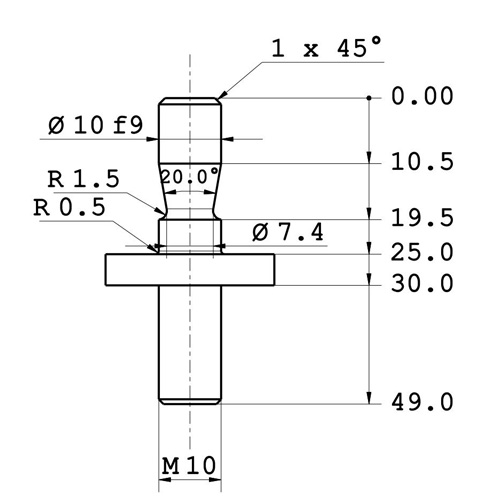

Core pins, Ejector pins & other precision pins

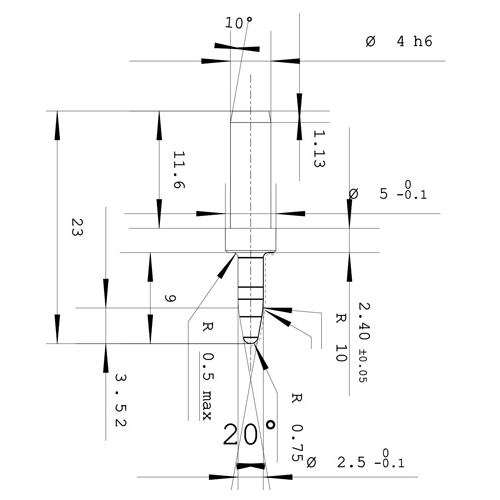

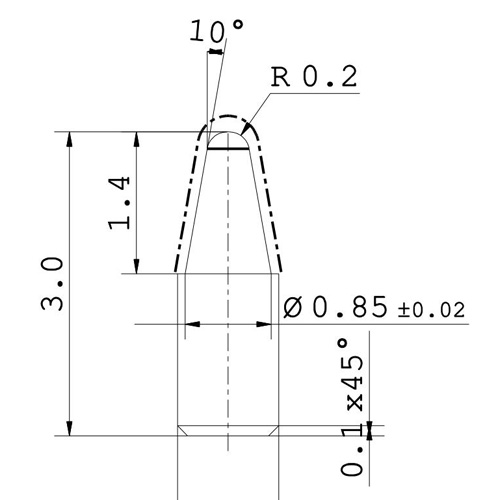

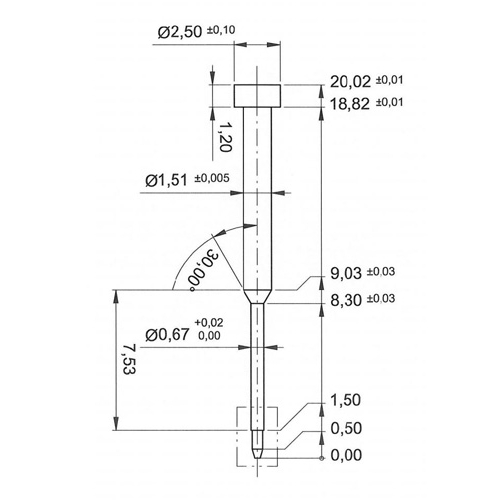

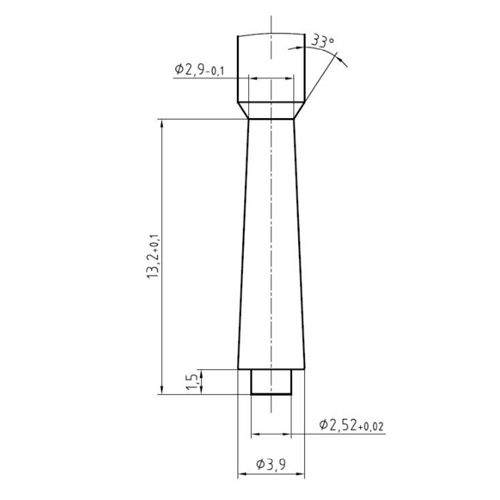

GS Machining Co., LTD offers a complete line of custom core pins, ejector pins & other pins with steel and tungsten carbide, such as core pins with customized ends, blade ejector pins, stepped ejector pins, straight ejector pins, nitrided ejector pins etc. They are applied to cold forming, plastic injection and die casting industries. We has the engineering expertise and experiences to supply special and custom core pins, ejector pins & other pins for our customer’s existing as well as new applications. Our good quality products result in our clients having improved in-plant productivity and quality performance as well as reduced manufacturing costs.

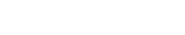

Also known as knockout and forged pins, use these pins to push parts out of molds. Pins are precision-ground to tight tolerances and hardened for strength and wear resistance. They makes plastic molding easier, preventing flash and resin waste. H13 tool steel pins resist rapid changes in temperature. M2 tool steel pins withstand high temperatures.

Made from H13 tool steel, these ejector pins are strong, hard, and resist wear. They’ve been surface hardened with nitriding, which adds more strength and wear resistance.

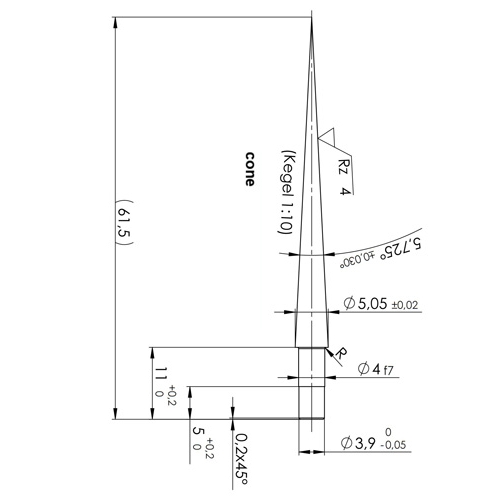

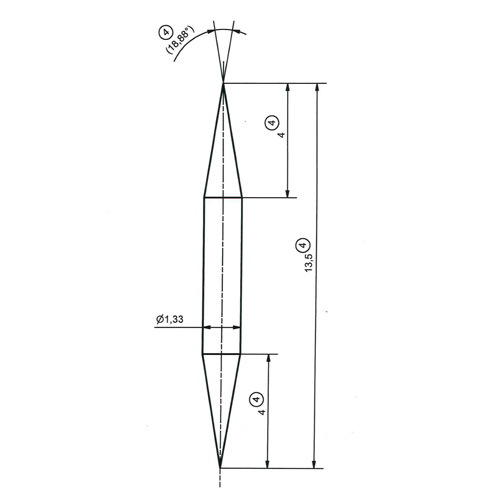

Use core pins to form small holes, or use them to perforate parts. They can be machined to fit your application. They’re ground to tight tolerances. M2 tool steel pins resist wear and stay sharp at high temperatures.

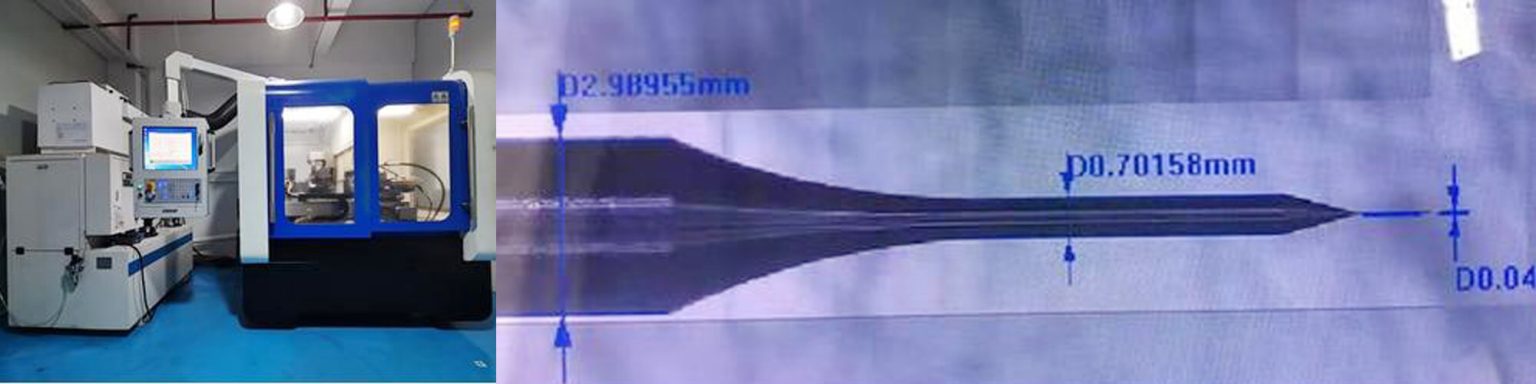

Meanwhile, we strongly recommend micro tungsten carbide core pins to you. They are made by our CNC grinding machine. Minimum diameter can reach 0.04mm with tolerance 0.001mm. Oblongs, Square, cylindrical, Hex are all available.

Why Choose Us?

Response

Response in 12 hours and comprehensive quotation will be offered in 24 hours. Valuable advices will be offered from our experienced team.Advanced Equipments

Wire-EDM from Seibu of Japan, Mirror-EDM from MITSUBISHI of Japan, CNC Grinding Machines etc.Competitive Price

Located in World Manufacturing City: Dongguan, Guangdong, China. Thanks to complete supply chain here, Competitive price can be offered.No MOQ Limitation

One piece is acceptable and No MOQ limitation. You can have a free choice on your order’s quantity.

Free Samples

Free samples can be provided. Avoiding any quality deviation before placing an order.100% Quality Control

100% quality control during production and before delivery. QC reports can be offered together with delivery.On-Time Delivery

Products delivered by days, not weeks. For simple parts, 3-5 days is available.After-sale Service

If you aren’t satisfied with our parts, refund your money or replacements will be arranged. No risks of losing money.

Clients